Maintenance

What is the CMMS system?

CMMS or Computerised Maintenance Management System is a class of IT systems responsible for repair management and maintenance in an enterprise, institution or organization. A system designed to help and improve the work of maintenance departments or services. In the industrial environment, the use of this type of tools is absolutely justified and is becoming more and more popular.

System CMMS

Computerized maintenance management system (CMMS)

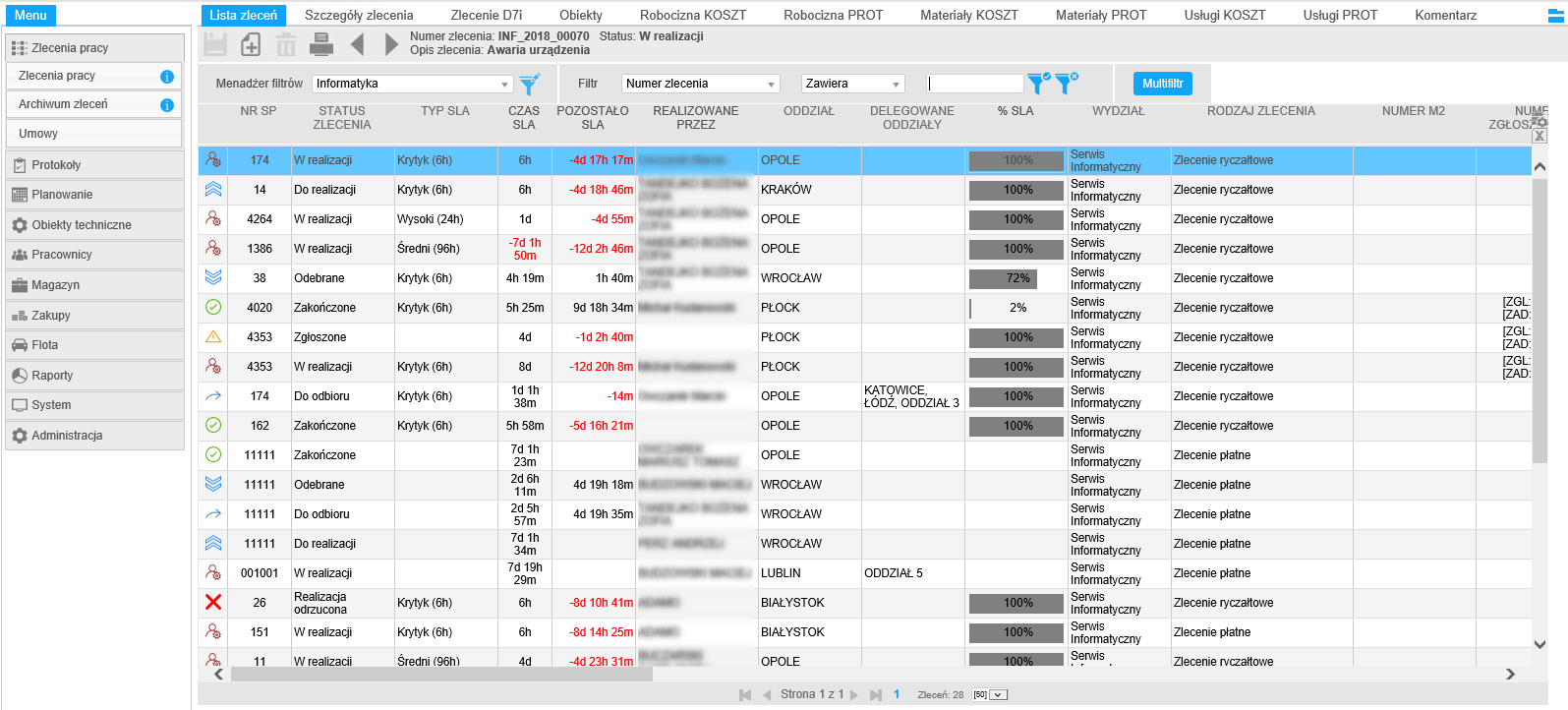

The CMMS system automates most of the logistics functions performed by maintenance personnel and management. These systems have many possibilities and advantages over manual maintenance tracking systems.

Depending on the complexity of the selected system, common CMMS features may include:

- Generate work orders, prioritize, and track by component.

- Historical tracking of all generated work orders, which can be sorted by equipment, date, respondent, etc.

- Tracking of scheduled and unplanned maintenance.

- Storage of maintenance procedures and all warranty information by component.

- Retention of all technical documentation or procedures by component.

- Real-time reports of current work.

- Generate preventive maintenance orders based on calendar or time of execution.

- Track budget and labor utilization by component, as well as shortest, median, and longest work order close times by component.

- Full control of spare parts with the possibility of automatic re-ordering of materials to the warehouse.

- Mobile application facilitating data entry and generating work orders.

- External options for calling / sending the service.

CMMS system

What are the benefits of implementing a CMMS system?

One of the biggest advantages of CMMS is the elimination of paperwork for work records and manual tracking of activities, which allows staff to become more productive. It should be noted that the functionality of the CMMS lies in its ability to collect and store information. The CMMS does not make decisions, but rather provides the maintenance services with precise information influencing the operational efficiency of the facilities.

Benefits of using the CMMS system

Thanks to the CMMS, it is possible to optimize the outlays for the maintenance of assets as a function of the failure rate analysis of machines and devices, the failure of which may have an impact on the threat to human life or environmental contamination.

CMMS in practice

The CMMS system is a tool designed for practical use in maintenance. Depending on the sophistication of the software package, different analytical tools are available for the enterprise. The system allows, inter alia, to:

- Digitization of the maintenance department and minimization of paper documentation, which significantly improves the work of employees and allows for better organization of the maintenance department.

- Efficient management of warehouse, production resources and spare parts.

- Planning of preventive and service activities.

Increasingly, CMMS software packages are hosted by vendors in the cloud and available on the network in the SaaS model. Increasingly, attention is paid to the various requirements related to the maintenance and management of infrastructure. Therefore, there are various applications on the market that can help you control the day-to-day operation of your facility. Due to the disadvantages of local CMMS systems, we observe the growing popularity of SaaS (Software as a Service) solutions, which are becoming more and more available in terms of infrastructure, price and access to high-speed internet connections. That is why every company can afford the possibility of implementing a CMMS system in the cloud.

SaaS software is the most advanced solution that ensures automatic configuration of applications and servers, makes IT infrastructure requirements negligible, and allows you to maintain all the advantages of a local CMMS system, while significantly reducing costs and effort related to software maintenance.

Is the CMMS system profitable?

Computerized maintenance management software varies in complexity, price, and industry specifics. Note that CMMS is sometimes interchangeable with enterprise resource management (EAM) systems. However, experts say, EAM solutions typically provide better functionality to support a variety of resources, such as physical machines or IT equipment, that can be centrally accessed throughout the enterprise. On the contrary, CMMS is usually limited to physical resources within a network of small objects or even to a single location.

Currently, CMMS and EAM are not mutually exclusive. They are often integrated with each other and with the ERP system. Although the basic functions of CMMS developed 25 years ago are still the basis of such programs, we are seeing the development of mobile technology and the use of cloud computing.

The costs of equipment downtime and production stoppages are enormous, so prevention and frequent inspections are very important to minimize the risk of failure. The maintenance department should also keep an eye on the contents of the spare parts inventory, as in the event of a machine failure, you may find that the defective parts are not in stock, so wait two weeks before they can be delivered. This should not be the case, as it will significantly increase the downtime of the equipment and thus increase the cost due to the omission of the machine in the production process or cause production stoppage for critical equipment.

Support for the work of conservators

In order to support and improve the work of conservators, computer systems have been developed that are increasingly used by companies. An example of such a system is CMMS. These systems provide access to all information about the machine park, give the possibility to report a fault or a current failure, and also allow the staff to manage it. One of the main advantages of this system is the ability to control warehouses and devices in the enterprise by creating a structure in the system and adapting it.